Titanium Alloy Welding

Ọ bụ otu akụkụ alloy mejupụtara β-phase siri ike ngwọta. Enweghị ọgwụgwọ okpomọkụ, ọ nwere ike dị elu. Mgbe emenyụ na ịka nká, alloy na-aga n'ihu. Otu nzọụkwụ na-ewusi ike, ike okpomọkụ ụlọ nwere ike iru 1372 ~ 1666 MPa; Ma nkwụsi ike nke okpomọkụ adịghị mma, e kwesịghị iji ya mee ihe na elu okpomọkụ.

Ọ bụ biphasic alloy, nwere ezigbo ihe zuru oke, nkwụsi ike nhazi dị mma, ịdị mma siri ike, plasticity na ihe nrụrụ okpomọkụ dị elu, nwere ike ịdị mma maka nhazi nrụgide dị ọkụ, nwere ike imenyụ, ịka nká iji mee ka alloy sikwuo ike. The ike mgbe okpomọkụ ọgwụgwọ bụ banyere 50% ~ 100% elu karịa na mgbe annealing; High okpomọkụ ike, nwere ike na-arụ ọrụ na 400 ℃ ~ 500 ℃ okpomọkụ ruo ogologo oge, ya thermal kwụsie ike dị ala ka α titanium alloy.

N'ime alloys titanium atọ, ndị a na-ejikarị eme ihe bụ α titanium alloy na α + β titanium alloy; Ọrụ ịkpụ nke α titanium alloy kacha mma, sochiri α + β titanium alloy, na β titanium alloy kacha njọ. α titanium alloy code maka TA, β titanium alloy code maka TB, α + β titanium alloy code maka TC.

Titanium alloy nwere ike kewaa n'ime okpomọkụ na-eguzogide alloy, elu ike alloy, corrosion eguzogide alloy (titanium - molybdenum, titanium - palladium alloy, wdg), ala okpomọkụ alloy na pụrụ iche alloy ọrụ (titanium - ígwè hydrogen nchekwa ihe na titanium - nickel ebe nchekwa. alloy). E gosipụtara ihe mejupụtara na ihe onwunwe nke alloys ndị a na-ahụkarị na tebụl.

Enwere ike nweta usoro nhazi oge dị iche iche na microstructure nke ihe ọkụkụ na-ekpo ọkụ na-ekpo ọkụ na titanium site n'ịgbanwe usoro ọgwụgwọ okpomọkụ. A na-ekwenyekarị na ụlọ ndị dị mma na-arụ ọrụ nke ọma nwere plasticity ka mma, nkwụsi ike okpomọkụ na ike ike ọgwụgwụ. Ọdịdị spiculate nwere ogologo ịdịte aka dị elu, ike na-akpụ akpụ na ike mgbaji. Ngwakọta agwakọta dị nhata na agịga dị ka agịga nwere njirimara zuru oke karịa. Titanium bụ ụdị metal ọhụrụ, arụmọrụ nke titanium metụtara ọdịnaya nke carbon, nitrogen, hydrogen, oxygen na adịghị ọcha ndị ọzọ, ihe adịghị ọcha titanium iodide dị ọcha adịghị karịa 0.1%, mana ike ya dị ala, nnukwu plasticity. .

Njirimara nke 99.5% titanium dị ọcha bụ ndị a: njupụta ρ = 4.5g / cubic cm, ebe agbaze 1725 ℃, conductivity thermal λ = 15.24W / (mK), ike ike σb = 539MPa, elongation δ = 25%, ngalaba shrinkage ψ = 25%, modulus na-agbanwe E = 1.078 × 105MPa, ike HB195. Njupụta nke titanium alloy bụ n'ozuzu banyere 4.51g / cubic centimita, naanị 60% nke ígwè, ike nke dị ọcha titanium dị nso na ike nke nkịtị ígwè, ụfọdụ elu ike titanium alloy karịrị ike nke ọtụtụ alloy structural ígwè. Ya mere, ike a kapịrị ọnụ (ike / njupụta) nke titanium alloy dị ukwuu karịa nke ihe nhazi ígwè ndị ọzọ, dị ka e gosiri na Tebụl 7-1. Ọ nwere ike ịmepụta akụkụ na akụkụ nwere ike unit dị elu, ezigbo isi ike na ịdị arọ dị arọ. Ka ọ dị ugbu a, a na-eji alloys titanium mee ihe n'ụdị injin, ọkpụkpụ, akpụkpọ anụ, ihe ngbochi na ngwa ọdịda.

Zitere anyị ozi gị:

-

Akụkụ aluminom CNC Machining

-

Aluminium Mpempe akwụkwọ Metal Metal

-

Akụkụ Axis High Precision CNC Machining Parts

-

Akụkụ CNC Machined maka Italy

-

Akụkụ CNC Machining Aluminom

-

Nrụpụta akụkụ akpaaka

-

Titanium Alloy Forgings

-

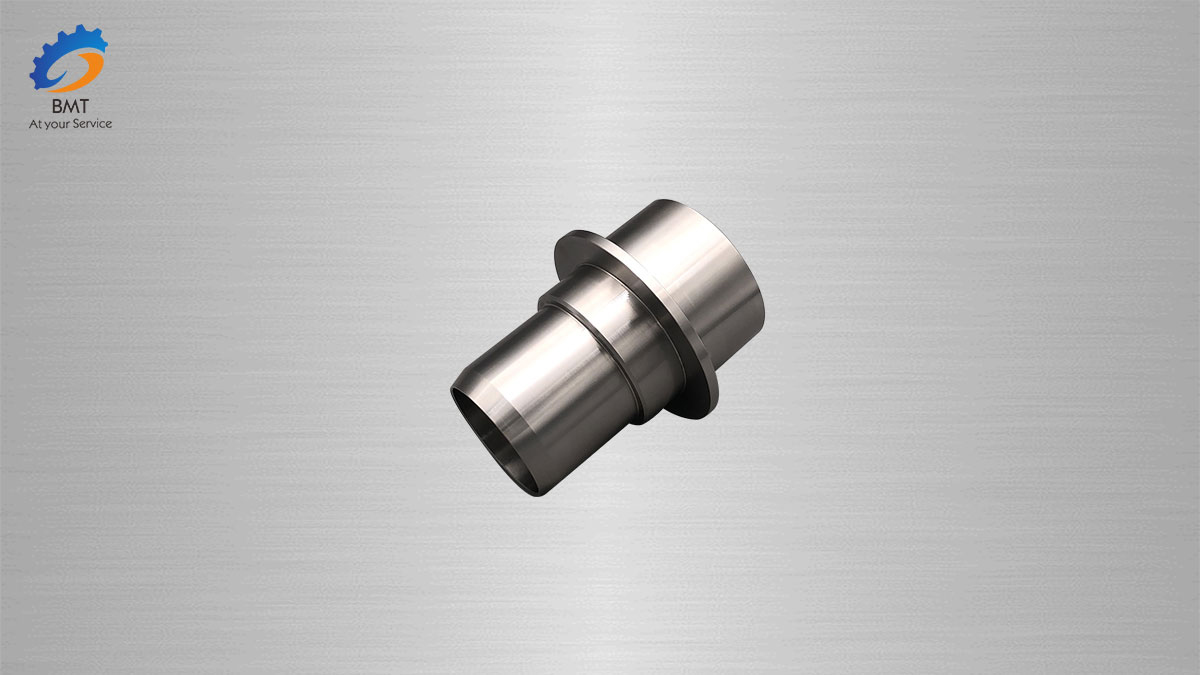

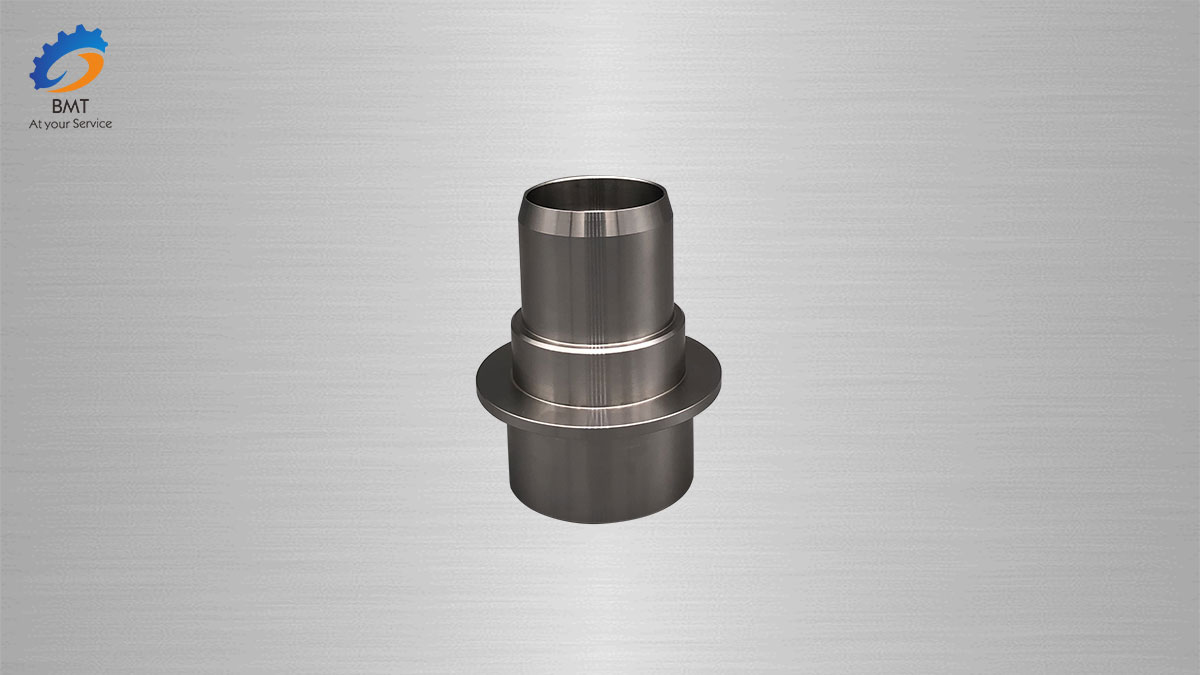

Titanium na Titanium Alloy Fittings

-

Titanium na Titanium Alloy Forgings

-

Titanium na Titanium Alloy Wires

-

Ogwe Titanium

-

Ọkụ/tube na-enweghị nkebi Titanium

-

Ọkụ/tube welded Titanium