Titanium na Titanium Alloy Wires

Titanium dị ọcha bụ ọla ọcha ọlaọcha, nke nwere ọtụtụ ihe mara mma. Titanium nwere njupụta nke 4.54g/cm3, 43% dị ọkụ karịa ígwè ma dị arọ karịa magnesium metal a ma ama. Mana ike igwe dị ihe dịka nchara, ike okpukpu abụọ ka aluminom na ugboro ise siri ike karịa magnesium. Titanium na-eguzogide okpomọkụ dị elu ma nwee ebe mgbaze nke 1942K, ihe fọrọ nke nta ka ọ bụrụ 1000K dị elu karịa ọla edo na ihe fọrọ nke nta ka ọ bụrụ 500K dị elu karịa ígwè.

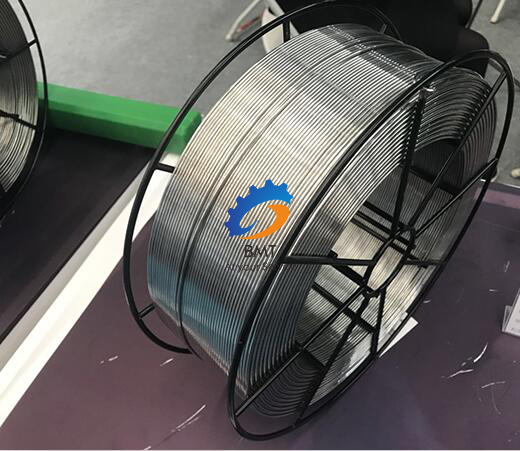

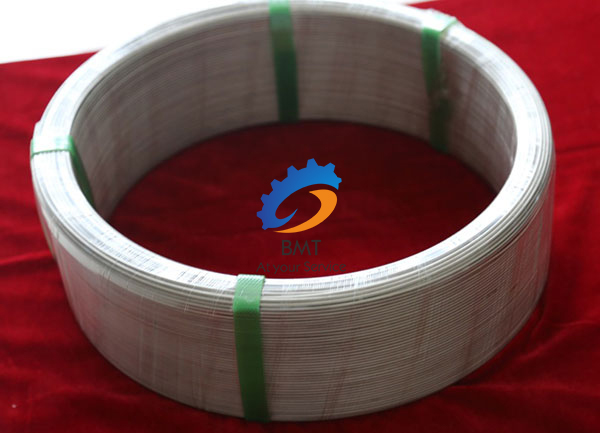

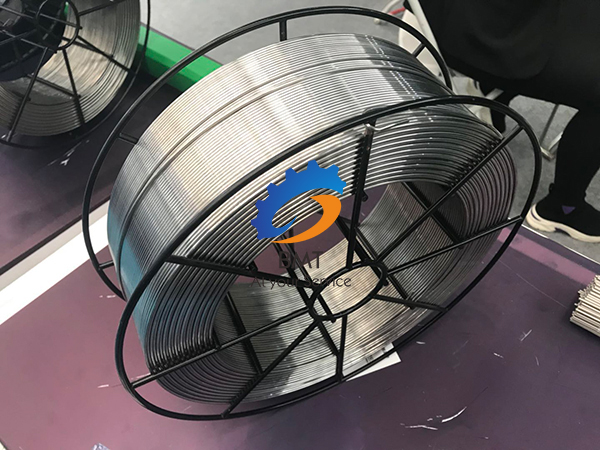

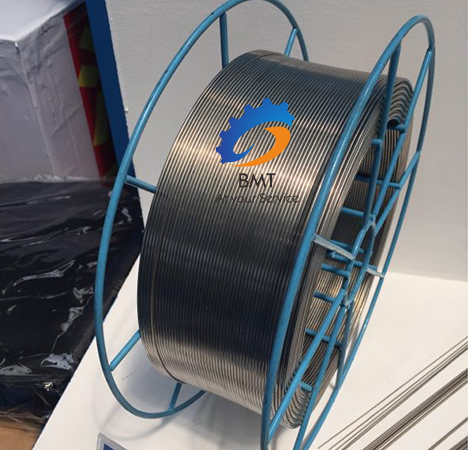

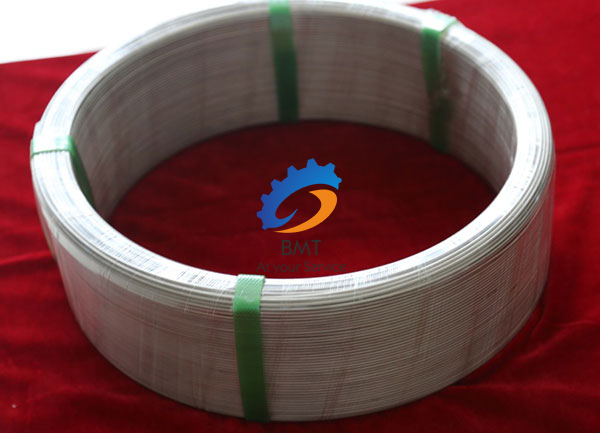

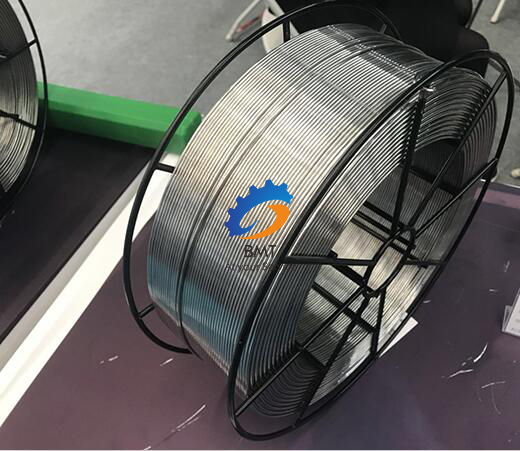

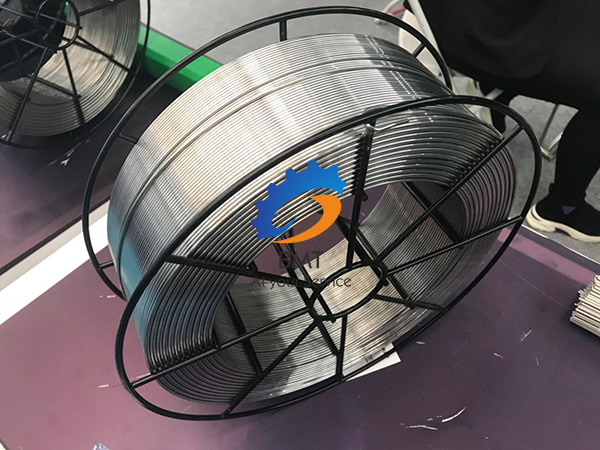

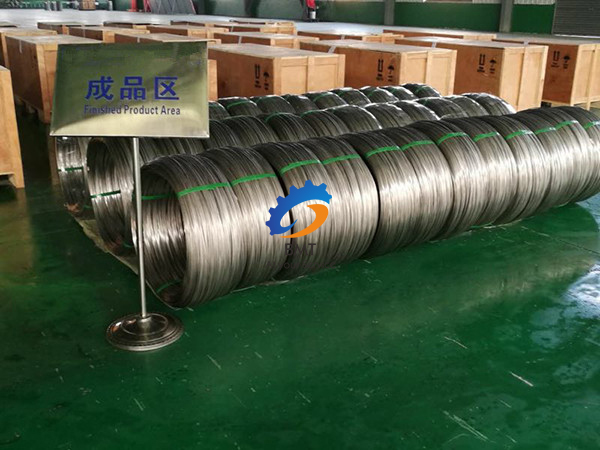

A na-ekewa waya titanium n'ime: waya titanium, waya alloy, waya anya ugogbe anya dị ọcha, waya kwụ ọtọ, waya titanium dị ọcha, waya ịgbado ọkụ, waya titanium nghọta, waya diski titanium, waya na-egbuke egbuke, waya titanium ọgwụ, waya titanium nickel alloy waya .

Nkọwapụta waya Titanium

A. Nkọwa waya titanium: φ0.8-φ6.0mm

B. Ugo titanium waya nkọwa: φ1.0-φ6.0mm pụrụ iche titanium waya

C. Nkọwa waya Titanium: φ0.2-φ8.0mm nwere nkwudo pụrụ iche

Ọkọlọtọ:GB/T,GJB,AWS,ASTM,AMS,JIS

Ọkwa nke Titanium Waya

GR1, GR2, GR3, GR5, GR7, GR9, GR11, GR12, GR16, wdg.

Ubi ngwa nke Titanium Waya

Ụlọ ọrụ ndị agha, ahụike, ngwa egwuregwu, iko, ọla ntị, uwe isi, mkpuchi electroplating, waya ịgbado ọkụ na ụlọ ọrụ ndị ọzọ.

Steeti Titanium Wire

Steeti na-akụda mmụọ (M)

Ọnọdụ ọrụ na-ekpo ọkụ (R)

Ọnọdụ ọrụ oyi (Y)

(Annealing, Ultra-generation Testing)

Elu nke Titanium Waya

N'elu elu ma ọ bụ na-egbuke egbuke

Waya Titanium na-etolite carbide kwụsiri ike nke nwere ike siri ike na carbon. A na-ekpebi uto nke oyi akwa carbonized n'etiti titanium na carbon site na ọnụego mgbasa nke titanium na oyi akwa carbonized.

Solubility nke carbon na titanium dị ntakịrị, ruru 0.3% na 850X: ma na-ebelata ihe dịka 0.1% na 600C B N'ihi obere solubility nke carbon na titanium, a na-enweta ike elu elu naanị site na titanium carbide oyi akwa na akimbo ya. oyi akwa n'okpuru. Carburizing ga-rụrụ n'okpuru ọnọdụ nke ikuku oxygen, n'ihi na elu oyi akwa hardness nke ntụ ntụ a na-ejikarị maka carburizing ígwè megide elu nke carbon monoxide ma ọ bụ oxygen-nwere carbon monoxide bụ ruo 2700MPa na 8500MPa, na ntupu. Ọ dị mfe ịpụpụ.

Ngwakọta kemịkalụ ihe dị

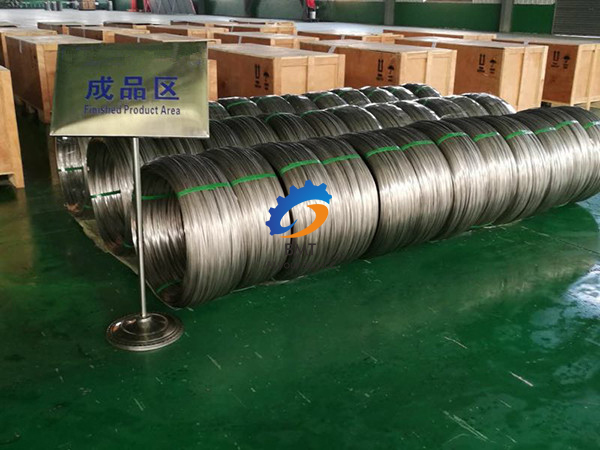

Nrụpụta (oke na nkeji nke ịtụ):Enweghị oke, dịka iwu siri dị.

Etiti oge:Oge ọgwụgwọ n'ozuzu bụ ụbọchị 30. Agbanyeghị, ọ dabere na ọnụọgụ nke usoro ahụ nke ọma.

Ụgbọ njem:Ụzọ njem n'ozuzu bụ site n'oké osimiri, site na Air, site Express, site na ụgbọ oloko, nke ndị ahịa ga-ahọrọ.

Nkwakọ ngwaahịa:

- A ga-eji okpu plastik ma ọ bụ kaadiboodu chebe nsọtụ ọkpọkọ.

- Ngwa niile a ga-akwakọba iji chebe nsọtụ na ihu.

- A ga-akwakọba ngwongwo ndị ọzọ niile site na paịlị ụfụfụ yana nkwakọ ngwaahịa plastik metụtara na ihe plywood.

- Osisi ọ bụla a na-eji kwakọba ga-adị mma iji gbochie mmetọ site na kọntaktị na akụrụngwa eji eme ihe.

.jpg)

N'ụzọ dị iche, n'okpuru ọnọdụ nke deoxygenation ma ọ bụ decarburization, a pụrụ ịmepụta obere oyi akwa nke titanium carbide mgbe carburized na unyi. Isi ike nke oyi akwa a bụ 32OUOMPa, nke kwekọrọ na ike nke titanium carbide. Omimi nke carburizing oyi akwa na-adịkarị karịa nke oyi akwa nitriding mgbe a na-eji nitriding n'okpuru otu ọnọdụ ahụ. N'okpuru ọnọdụ nke ịba ụba oxygen, a ghaghị ịtụle mmetụta nke ịmịnye oxygen na ịdị omimi siri ike. Ọ bụ naanị n'okpuru ọnọdụ nke ọkpụrụkpụ oyi akwa dị gịrịgịrị ka enwere ike ịmepụta ike nrapado zuru oke site na carburizing ntụ ntụ n'ime oghere ma ọ bụ na ikuku argon-methane. N'ụzọ dị iche, iji gas carburizing agent nwere ike ịmepụta oyi akwa titanium carbide siri ike na nke ọma. N'otu oge ahụ, hardening gbasaa kpụrụ na okpomọkụ n'etiti 950T: na 10201:. Site na mmụba nke ọkpụrụkpụ oyi akwa, oyi akwa TiC na-aghọwanye nke na-akụkpọ nkụ ma na-agbapụ. Iji zere nbanye nke carbon inclusions n'ime TiC oyi akwa n'ihi ire ere nke Reane, gas carburizing kwesịrị ime na gas inert nke nwere ihe mgbakwunye dose nke ihe dị ka 2% Reane. A na-enweta ike nke elu ala mgbe methane jiri ihe mgbakwunye propane mee carburized. Mgbe ike njikọ ahụ ruru OKPA na gas carburized propane na-eji, ọ bụ ezie na ọkpụrụkpụ oyi akwa a tụrụ atụ dị gịrịgịrị, ọ nwere nguzogide iyi kacha mma. A na-etinye mmiri n'ime hydrogen site na gas carburizing agent, mana a ga-ewepụ ya ọzọ mgbe a na-ekpochapụ agụụ.