Titanium na Titanium Alloy Forgings

Titanium na titanium alloys nwere uru nke njupụta dị ala, ike dị elu dị elu na ezigbo nguzogide corrosion, a na-ejikwa ya n'ọtụtụ ebe.

Titanium forging bụ usoro akpụ nke na-etinye ike mpụga na oghere metal titanium (Ewezuga efere) iji mepụta nrụrụ rọba, gbanwee nha, ọdịdị, na melite arụmọrụ. A na-eji ya rụpụta akụkụ igwe, ihe arụ ọrụ, ngwaọrụ ma ọ bụ oghere. Na mgbakwunye, dị ka usoro mmegharị nke ihe mmịfe ahụ na usoro mmegharị kwụ ọtọ na kwụ ọtọ nke ihe mmịfe ahụ (Maka ịgha akụkụ ndị dị gịrịgịrị, mmanu mmanu na nju oyi, na imepụta akụkụ mmepụta ngwa ngwa), ụzọ mmegharị ndị ọzọ nwere ike ịbawanye site na. iji ngwaọrụ akwụ ụgwọ.

Ụzọ ndị a dị n'elu dị iche iche, na ike ịgha ihe achọrọ, usoro, ọnụọgụ ihe eji eme ihe, mmepụta, nnabata akụkụ, na mmanu na ụzọ jụrụ oyi dịkwa iche. Ihe ndị a bụkwa ihe na-emetụta ọkwa nke akpaaka.

Forging bụ usoro nke iji plasticity nke metal nweta a plastic akpụ usoro na ụfọdụ udi na structuring Njirimara nke oghere n'okpuru mmetụta ma ọ bụ nrụgide nke ngwá ọrụ. The elu nke forging mmepụta bụ na ọ nwere ike ọ bụghị nanị na-enweta udi nke n'ibu akụkụ, kamakwa melite esịtidem Ọdịdị nke ihe onwunwe na melite n'ibu Njirimara nke n'ibu akụkụ.

1. Free Forging

A na-arụkarị akpụ akpụ n'efu n'etiti anwụ ma ọ bụ ebu dị larịị na-enweghị oghere. Ngwá ọrụ ndị a na-eji na-emepụta ihe n'efu dị mfe na ọdịdị, na-agbanwe agbanwe, dị mkpirikpi na usoro mmepụta ihe na ọnụ ala dị ala. Otú ọ dị, ike ịrụ ọrụ dị elu, ọrụ ahụ siri ike, nrụpụta dị ala, ịdị mma nke forgings adịghị elu, na ntinye ego nke igwe dị ukwuu. Ya mere, ọ dị mma maka iji ya mee ihe mgbe ọ nweghị ihe pụrụ iche chọrọ na arụmọrụ nke akụkụ ahụ na ọnụ ọgụgụ nke mpempe akwụkwọ dị ntakịrị.

2. Mepee Die Forging (Die Forging with Burrs)

A na-emezi oghere ahụ n'etiti modul abụọ nwere oghere ndị a kanyere, nke a na-eme ka a na-emepụta ihe dị n'ime oghere ahụ, na oke ígwè ahụ na-esi na oghere dị warara dị n'etiti abụọ ahụ na-anwụ anwụ, na-eme ka ọkpụkpụ na-agba gburugburu. N'okpuru nguzogide nke ebu na burrs gbara ya gburugburu, a na-amanye ígwè ahụ ka a pịa ya ka ọ bụrụ ọdịdị nke oghere ọkpụkpụ.

3. Mechie anwụ Forging (Die Forging without Burrs)

N'oge mechiri emechi anwụ forging usoro, ọ dịghị transverse burrs perpendicular ka ntụziaka nke anwụ ije na-guzobere. Oghere nke anwụ anwụ mechiri emechi nwere ọrụ abụọ: otu bụ maka imepụta oghere, nke ọzọ bụ maka iduzi.

4. Extrusion anwụ Forging

N'iji usoro extrusion maka ịnwụ anwụ, e nwere ụdị abụọ nke forging, n'ihu extrusion na azụ extrusion. Extrusion anwụ forging nwere ike rụpụta dị iche iche oghere na siri ike akụkụ, na ike nweta forgings na elu geometrical nkenke na denser esịtidem Ọdịdị.

5. Multi-Directional Die Forging

A na-eme ya na igwe na-anwụ anwụ nke ọtụtụ ntụziaka. Na mgbakwunye na ịkụ ọkpọ kwụ ọtọ na ntụtụ plọg, igwe na-ahụ maka anwụ anwụ nwere ọtụtụ ụzọ nwekwara plunger abụọ kwụ ọtọ. Enwere ike iji ihe na-adọpụ ya mee ihe maka ịkụ ọkpọ. Nrụgide nke ejector dị elu karịa nke akwụkwọ hydraulic nkịtị. Iji buru ibu. Na multi-directional anwụ forging, ihe mmịfe na-eme ọzọ na nkwonkwo na workpiece si vetikal na kehoraizin ntụziaka, na otu ma ọ bụ karịa perforation punches na-eji na-eme ka ígwè eruba n'èzí si n'etiti oghere iji nweta nzube nke ejuputa na. oghere.

6. Kewara Forging

Iji mepụta nnukwu forgings na nrụgide hydraulic dị ugbu a, enwere ike iji ụzọ ịgha mkpụrụ akụkụ dị ka akụkụ anwụ anwụ na-agbapụta na efere shim die forging. Akụkụ nke usoro ịhịa aka n'ahụ na-anwụ anwụ bụ ịhazi akụkụ akpụ akpụ n'otu akụkụ, na-ahazi otu akụkụ n'otu oge, yabụ tonna ngwa akụrụngwa achọrọ nwere ike ịdị obere. N'ikwu okwu n'ozuzu, enwere ike iji usoro a mee ihe n'ịhazi nnukwu forgings na igwe igwe hydraulic dị ọkara.

7. Isothermal anwụ Forging

Tupu akpụ akpụ, a na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ nke oghere, na okpomọkụ nke ebu na oghere na-anọgide na-abụ otu n'ime oge a na-emepụta ihe, nke mere na enwere ike nweta nnukwu nrụrụ n'okpuru ọrụ nke obere nrụrụ ike. . Isothermal anwụ forging na isothermal superplastic die forging yiri nnọọ, ihe dị iche bụ na tupu anwụ forging, oghere kwesịrị ịbụ superplasticized [i] ime ka o nwere equiaxed grains [ii].

Titanium alloy forging usoro na-ọtụtụ ebe na-eji ụgbọ elu na aerospace mmepụta (Usoro nhazi nke Isothermal anwụejirila na-emepụta akụkụ injin na akụkụ nhazi ụgbọ elu), ọ na-aghọwanye ewu ewu na mpaghara mmepụta ihe dị ka ụgbọala, ọkụ eletrik, na ụgbọ mmiri.

Ka ọ dị ugbu a, iji ihe ndị titanium eme ihe dị oke elu, na ọtụtụ ubi ndị nkịtị aghọtabeghị nke ọma mma nke alloys titanium. Site na ọganihu sayensị na-aga n'ihu na-aga n'ihu, nkwadebe nke titanium na titanium alloy technology ngwaahịa ga-adị mfe ma ọnụ ahịa nhazi ga-adị ala ma dị ala, a ga-egosipụtakwa amara nke titanium na titanium alloy n'ọtụtụ ebe.

Using extrusion usoro maka anwụ forging, e nwere ụdị abụọ nke forging, Forward Extrusion na Reverse Extrusion. Extrusion Die Forging nwere ike rụpụta akụkụ dị iche iche nwere oghere na nke siri ike, ma nwee ike nweta forgings nwere oke geometrical na nhazi dị n'ime.

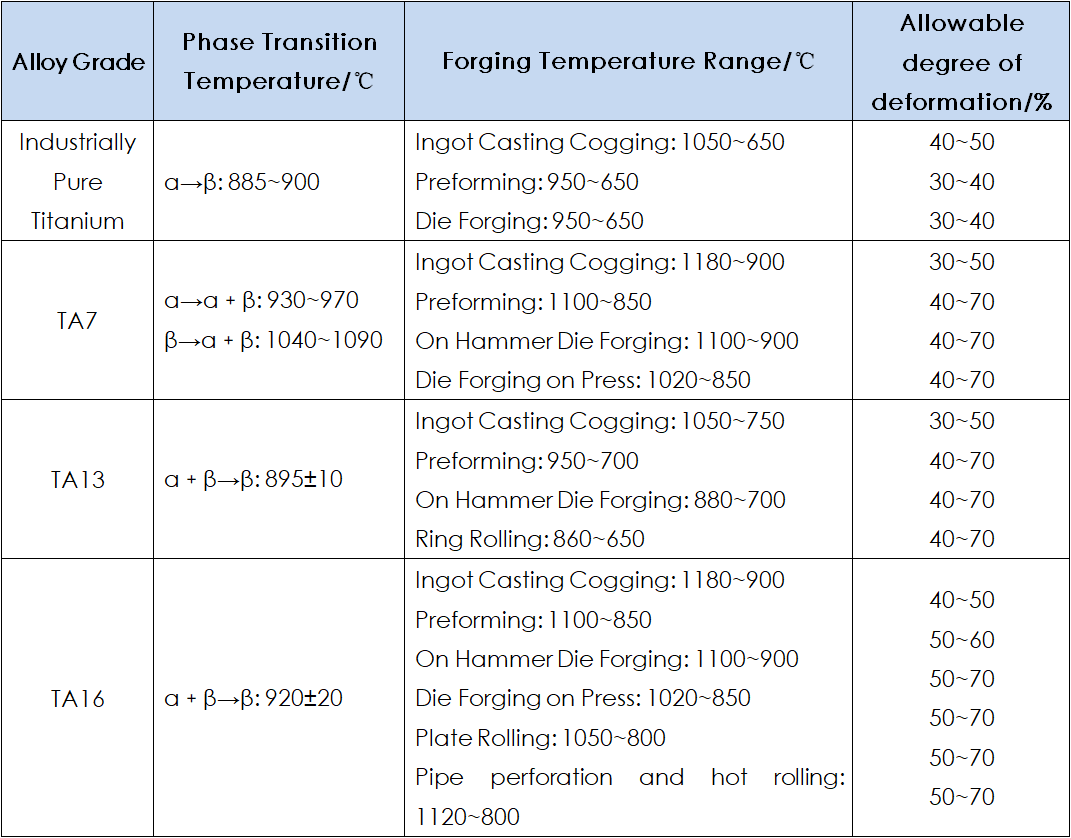

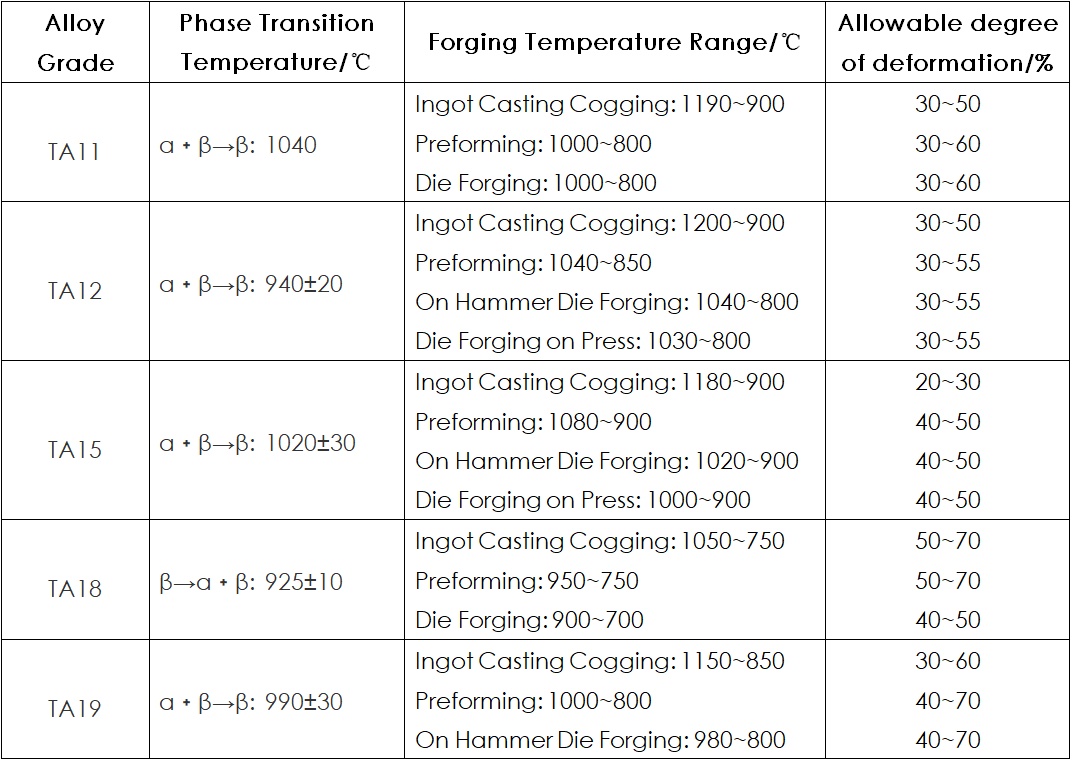

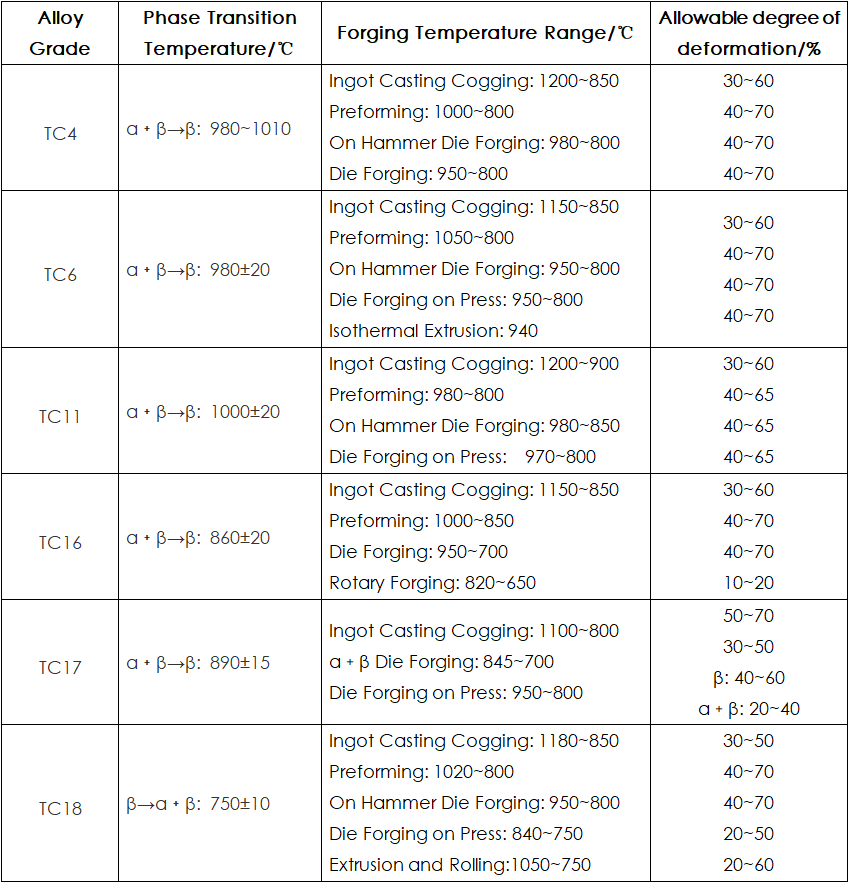

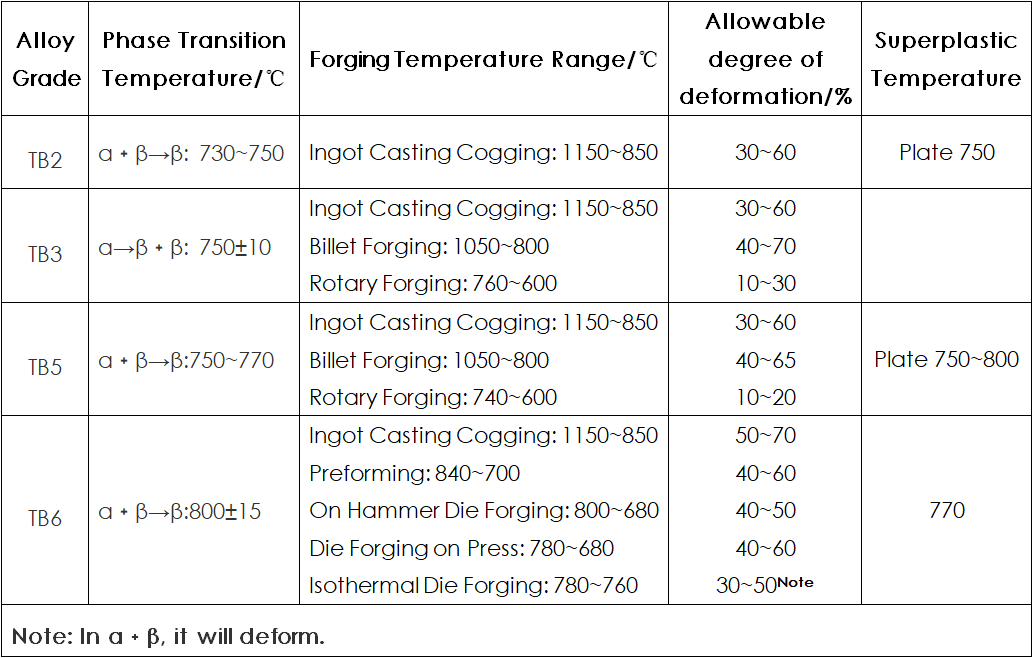

Dị ka usoro nyocha nyocha na ahụmịhe mmepụta mmepụta ihe si dị, a na-achịkọta data nhazi arụmọrụ nke ụdị α, nso-α-ụdị, α﹢β-ụdị na nso-β-ụdị titanium alloys na Tebụl 1 ruo Tebụl 4, n'otu n'otu.

Site na data dị na Tebụl 1 ruo Tebụl 4, a pụrụ ịhụ na okpomọkụ nke ọtụtụ titanium alloy ingots dị n'etiti 1150 ° C ruo 1200 Celsius C, na okpomọkụ nke mbụ nke ụfọdụ titanium alloy ingots dị na nso. nke 1050 ° C ruo 1100 ° C; Mpaghara okpomọkụ abụọ a dị na mpaghara β-phase zone, na nke mbụ dị elu karịa mgbanwe mgbanwe oge n'ihi ọtụtụ ihe kpatara ya.

Nke mbụ, alloy nwere nhazi dị elu na nguzogide nrụrụ dị ala na mpaghara mpaghara β. Iji gbalịsie ike maka ogologo oge ịgha mkpụrụ, ọ bara uru iji melite mmepụta ihe; Nke abuo, a na-ebunye billet maka oge ntoju ingot ka ọ bụrụ oghere maka ịgha ahịhịa. Mgbe a na-emepụta ihe na nnukwu nrụrụ, enwere ike imeziwanye ihe owuwu ahụ na-enweghị emetụta arụmọrụ nke nrụrụ ahụ. Ya mere, a na-ahọrọ usoro na-arụpụta ihe dị elu.

Site na data dị na Tebụl 1 ruo Tebụl 4, a ga-ahụ na ọnọdụ okpomọkụ mbụ nke ịnwụ anwụ na-agbapụta na ndị nta akụkọ abụghị naanị na ọ dị ala karịa nke mbụ na-eme ka okpomọkụ nke ingot billet, kamakwa ọ dị ala karịa α / β oge mgbanwe okpomọkụ. site na 30 ℃ ~ 50 ℃. Ọtụtụ titanium The anwụ forging okpomọkụ nke alloy bụ na nso nke 930 ℃ ~ 970 ℃, nke bụ iji hụ na deformation na α﹢β frasi mpaghara inweta chọrọ microstructure na Njirimara nke forging. Ebe ọ bụ na forging hammer die forging chọrọ multiple igbu na ọrụ oge bụ ogologo, ndị nwụrụ forging kpo oku okpomọkụ nke ya okokụre forgings nwere ike n'ụzọ kwesịrị ekwesị mụbara site 10 ℃ ~ 20 ℃ karịa nke pịa forging. Otú ọ dị, iji hụ na Ọdịdị na n'ibu Njirimara nke titanium alloy okokụre forgings, Ya mere, ikpeazụ forging okpomọkụ nke forging usoro kwesịrị ịchịkwa na α﹢β abụọ-phase mpaghara.

A pụkwara ịhụ ya site na data dị na Tebụl 1 ruo Tebụl 4 na mmalite mmalite okpomọkụ nke ọtụtụ titanium alloy preforms dị ntakịrị elu karịa ma ọ bụ nso nso oge mgbanwe okpomọkụ. Okpomọkụ α/β izizi nke usoro mgbanwe dị ka preforming dị ala karịa okpomoku ingot na-eto eto, ma dị elu karịa okpomoku izizi nke ịnwụ anwụ. Deformation na mpaghara okpomọkụ a ọ bụghị nanị na-elekọta arụpụtaghị ihe, ma na-akwadebekwa usoro dị mma maka ịgha mkpụrụ.

Isiokwu 1 Ịmepụta data arụmọrụ nke ụdị titanium α

Tebụl 2 Ịmepụta data arụmọrụ nke dị nso α-ụdị titanium alloy

Isiokwu 3 Ịmepụta data arụmọrụ nke α﹢β titanium alloy

Tebụl 4 Ịmepụta data arụmọrụ nke dị nso β-ụdị titanium alloy

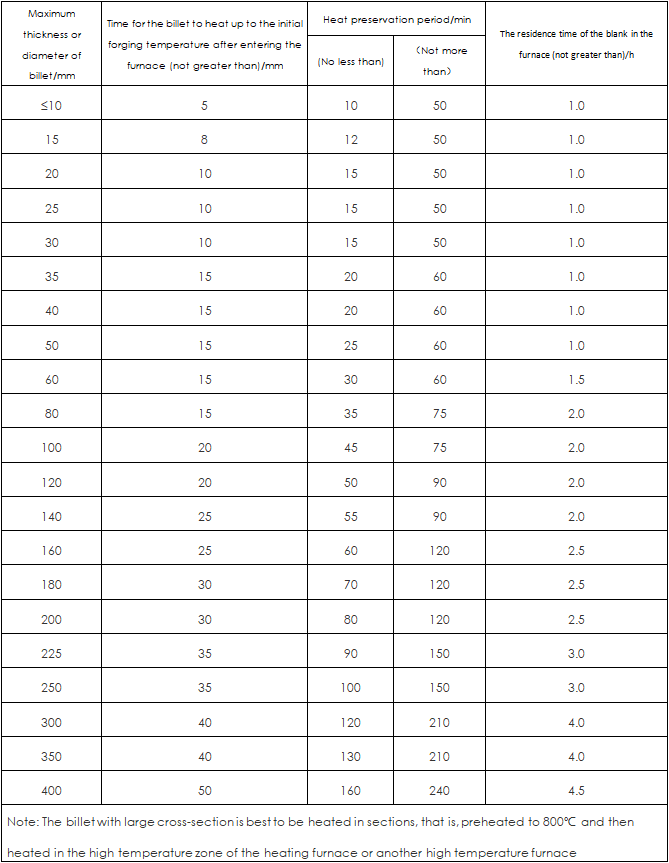

Tebụl 5 kpo oku na ijide oge titanium alloy oghere

BMT bụ nke pụrụ iche n'ịmepụta titanium adịchaghị adị na forging titanium alloy nke na-egosipụta ikike ọrụ dị mma, nkwụsi ike, nguzogide corrosion, njupụta dị ala na ike dị elu. BMT titanium ngwaahịa 'ọkọlọtọ mmepụta na usoro nchọpụta emeriela ma mgbagwoju nkà na ụzụ na machining siri ike nke titanium forging n'ichepụta.

Ihe nrụpụta titanium ziri ezi dị elu sitere na nhazi usoro ọkachamara yana usoro ji nwayọọ nwayọọ na-aga n'ihu. BMT titanium forging nwere ike tinye na nso site na obere ọkpụkpụ na-akwado ihe owuwu na nnukwu size titanium forging maka ụgbọ elu.

BMT titanium forgings na-ọtụtụ ebe na-eji na ọtụtụ ụlọ ọrụ, dị ka aerospace, Offshore engineering, mmanụ na gas, egwuregwu, nri, ụgbọ ala, wdg Anyị kwa afọ mmepụta ike bụ ruo 10,000 tọn.

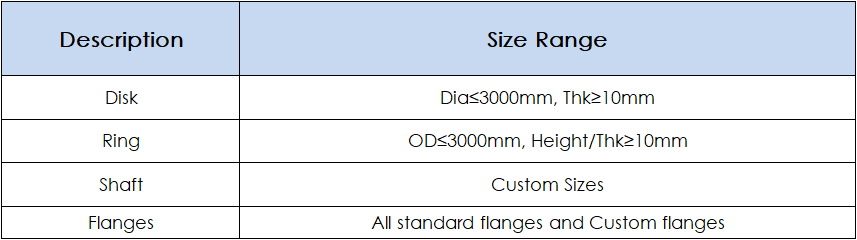

Oke oke:

Ngwakọta kemịkalụ ihe dị

Ngwakọta kemịkalụ ihe dị

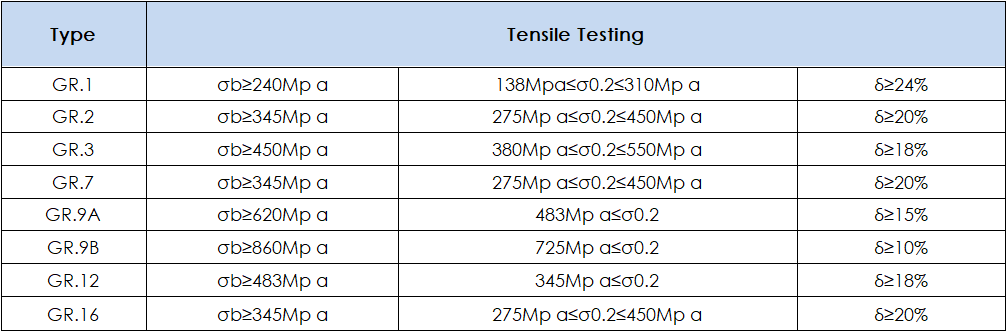

Nyocha nyocha:

- Nyocha ihe mejupụtara kemịkalụ

- Nnwale ihe eji arụ ọrụ

- Nnwale tensile

- Nnwale ọkụ

- Nnwale ire ọkụ

- Nnwale ịgbagọ

- Nnwale Hydro-Static

- Nnwale pneumatic (Nnwale nrụgide ikuku n'okpuru mmiri)

- Nnwale NDT

- Nnwale Eddy-Ugbu a

- Nnwale Ultrasonic

- Nnwale LDP

- Nyocha Ferroxyl

Nrụpụta (oke na nkeji nke ịtụ):Enweghị oke, dịka iwu siri dị.

Etiti oge:Oge ọgwụgwọ n'ozuzu bụ ụbọchị 30. Agbanyeghị, ọ dabere na ọnụọgụ nke usoro ahụ nke ọma.

Ụgbọ njem:Ụzọ njem n'ozuzu bụ site n'oké osimiri, site na Air, site Express, site na ụgbọ oloko, nke ndị ahịa ga-ahọrọ.

Nkwakọ ngwaahịa:

- A ga-eji okpu plastik ma ọ bụ kaadiboodu chebe nsọtụ ọkpọkọ.

- Ngwa niile a ga-akwakọba iji chebe nsọtụ na ihu.

- A ga-akwakọba ngwongwo ndị ọzọ niile site na paịlị ụfụfụ yana nkwakọ ngwaahịa plastik metụtara na ihe plywood.

- Osisi ọ bụla a na-eji kwakọba ga-adị mma iji gbochie mmetọ site na kọntaktị na akụrụngwa eji eme ihe.