Titanium na Titanium Alloy Bars

Enwere ike kewaa alloy Titanium ụzọ atọ dịka nhazi nke usoro: α alloy,(α+β) alloy na β alloy, nke TA, TC na TB na China gosipụtara n'otu n'otu.

① Alloy ahụ nwere ihe ụfọdụ nwere akụkụ α kwụsiri ike ma bụrụ nke mejupụtara α na steeti nha nhata. Alloys α nwere obere ike ndọda, ezigbo ike ọkụ, ezigbo weldability na ezigbo nguzogide corrosion. Ihe ọghọm bụ ike dị ala na ụlọ okpomọkụ, a na-ejikarị ya eme ihe dị ka ihe ndị na-eguzogide okpomọkụ na corrosion . α alloys nwere ogige ole na ole (Ti-2.5Cu).

② (α + β) alloy nwere ụfọdụ ihe ndị nwere ike α na-akwụsi ike na oge β, na microstructure nke alloy na nha nha nha bụ α-phase na β phase. na-ewusi ike site na ọgwụgwọ okpomọkụ, ma weldability adịghị mma. (α + β) alloys na-ejikarị eme ihe, na mmepụta nke Ti-6Al-4V alloys na-akpata ihe karịrị ọkara nke ihe niile titanium.

① β alloy nwere ọnụ ọgụgụ buru ibu nke ihe kwụsiri ike β nkeji, elu okpomọkụ β nkeji nwere ike idowe na ụlọ okpomọkụ.β alloy nwere ike kewaa okpomọkụ agwọ ọrịa β alloy (metastable β alloy na fọrọ nke nta metastable β alloy) na okpomọkụ kwụsie ike β alloy. The heat-treatable β alloy nwere magburu onwe ductility na quenched ala na ike nweta tensile ike nke 130 ~ 140kgf / mm2 site na ịka nká ọgwụgwọ.β alloys na-ejikarị eme ihe dị ka ike dị elu na elu siri ike ihe. Ọdịmma dị ịrịba ama, ọnụ ahịa, ogbenye ịgbado ọkụ. ịrụ ọrụ, nsogbu igwe.

Ụkpụrụ ntụtu aka

1: GB 228 Metallic tensile ule ụzọ

2: GB/T 3620.1 Titanium na titanium alloy ọkwa na chemical mejupụtara

3: GB / T3620.2 titanium na titanium alloy nhazi ngwaahịa chemical mejupụtara na mejupụtara ekwe ndiiche

GB 4698 Ụzọ maka nyocha kemịkalụ nke titanium sponge, titanium na titanium alloys

GB: GB/T2965-2007, GB/T13810, Q/BS5331-91

ọkọlọtọ American: ASTM B348, ASTM F136, ASTM F67, AMS4928

Nka na ụzụ chọrọ

1: Ngwakọta kemịkalụ nke titanium na titanium alloy bar ga-adaba na ndokwa nke GB / T 3620.1. Mgbe achọrọ nnwale ugboro ugboro, ndagide nke kemịkalụ a na-anabata ga-adaba na ihe GB/T 3620.2.

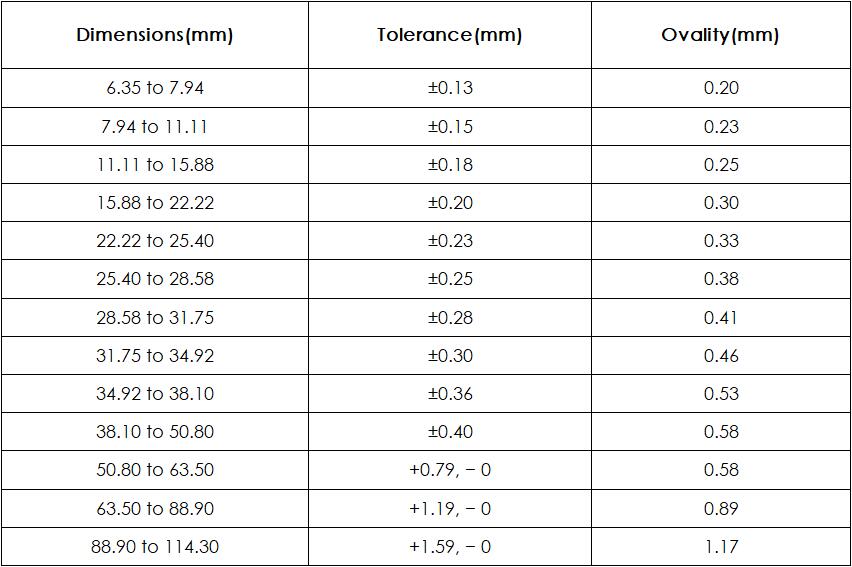

2: The dayameta ma ọ bụ n'akụkụ ogologo nke na-ekpo ọkụ na-arụ ọrụ mmanya na ya kwere ekwe ga-adaba na ndokwa na Table 1.

3: Mgbe arụ ọrụ na-ekpo ọkụ gasịrị, nkwụsị nke a na-ekwe ka dayameta nke oyi na-atụ oyi ga-agbaso ihe ndị dị na Tebụl 2 mgbe ị na-atụgharị (na-egweri) mmanya na-egbuke egbuke na ntụgharị oyi.

4: mgbe na-ekpo ọkụ nhazi site ụgbọ ala (egweri) ìhè mmanya nke roundness ekwesịghị ịbụ ihe karịrị ọkara nke size ndidi.

5: ogologo nke indeterminate ogologo nke obodo esichara bụ 300-6000mm, ogologo nke indeterminate ogologo nke annealed ala mmanya bụ 300-2000mm, na ogologo nke ofu ogologo ma ọ bụ abụọ ogologo kwesịrị ịdị n'ime nso nke indeterminate ogologo. .Ngbanwe nke a na-enye ohere nke ogologo oge a kapịrị ọnụ bụ + 20mm; A ga-etinyekwa ogologo nke ogologo okpukpu abụọ n'ime mpempe akwụkwọ nke mmanya ahụ, na onye ọ bụla ịkpụ ga-abụ 5mm. A ga-akọwapụta ogologo nke ogologo ogologo ma ọ bụ ogologo nke ogologo abụọ na nkwekọrịta.

Nkọwa: mpịakọta ¢8.0-- 40mm× L; Mkpesa ¢40-150 - mm x L

Metallographic Ọdịdị: dị ọcha titanium ọka size bụghị ihe na-erughị ọkwa 5, TC4 titanium alloy n'ahịrị na A1-A9.

Elu: elu ojii, elu a na-egbu maramara, elu a na-egbu maramara (H11, H9, H8)

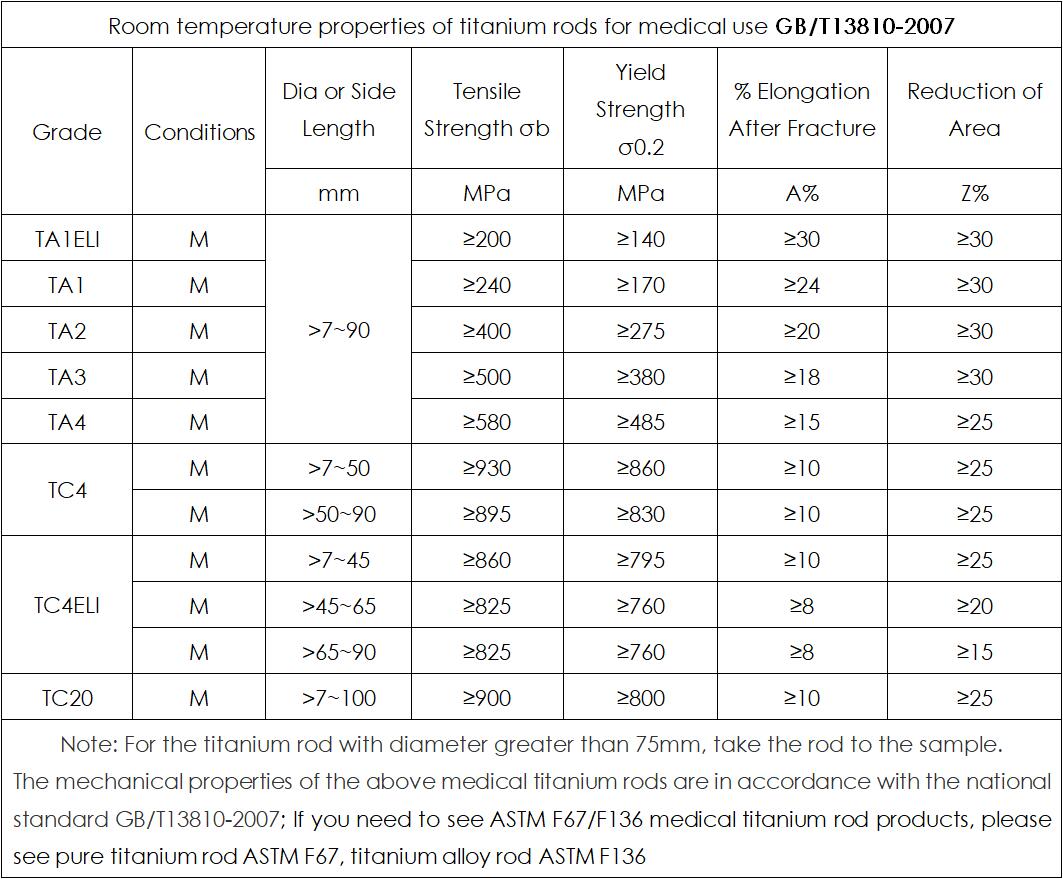

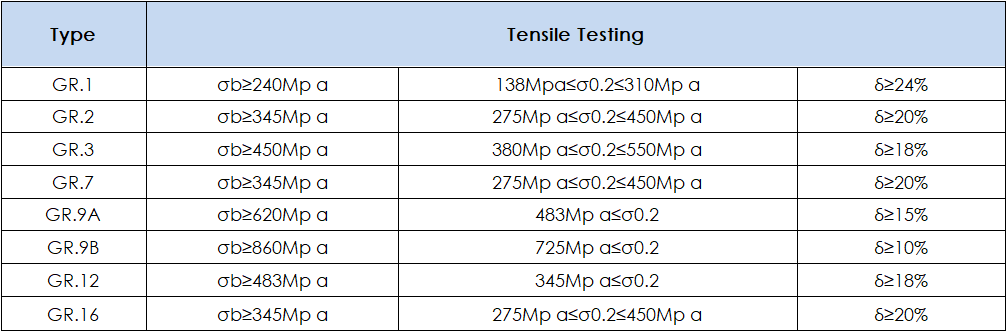

Arụmọrụ nke ọgwụ titanium mkpanaka (ụkpụrụ ntụaka:GB/T13810-2007,ASTM F67/F136).

Anyị na-emepụta ma na-ebupụ ASTM ọkọlọtọ titanium mmanya kwa afọ na Chinese Standard (GB) ọkọlọtọ titanium mmanya na titanium mmanya nke ọkọlọtọ ekwekọrịtara.

N'ịbụ ndị nọ n'ime ndị na-emepụta ihe ole na ole nwere ike ịghọta njikwa mma na usoro mmepụta dum, anyị na-arụ ọrụ nchịkwa siri ike site na nsị nke titanium sponge na ngwaahịa ndị emechara.

N'inwe ezigbo mma na nsochi na ọrụ na-enweghị atụ, anyị na-ere ngwaahịa gụnyere ụlọ mmanya titanium ọgwụ, mmanya polishing na titanium alloy n'ụwa niile. Anyị abụrụla otu n'ime ndị na-ebubata na ndị na-ebupụ ihe mgbochi titanium na China.

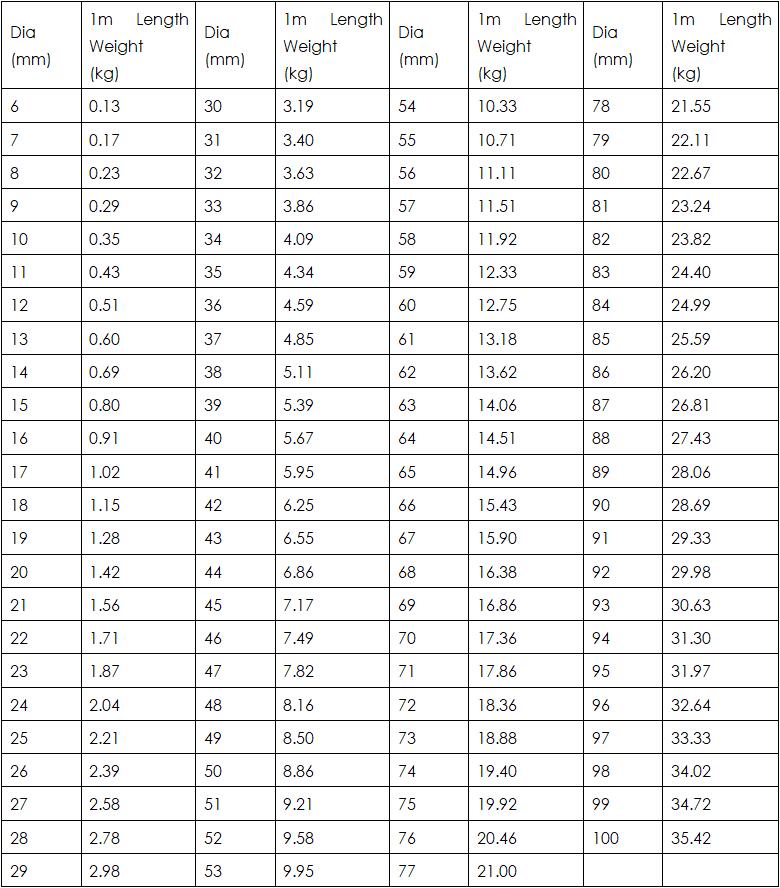

Oke oke: dayameta 6-200mm x Max 6000mm

Njirimara okpomọkụ nke ụlọ nke mkpanaka titanium maka ojiji ahụike GB/T13810-2007:

Nha anyị mere:

Akụkụ, ndidi na oke ovality:

Ngwakọta kemịkalụ ihe dị

Ngwakọta kemịkalụ ihe dị

Nyocha nyocha:

- Nnwale NDT

- Nnwale Ultrasonic

- Nnwale LDP

- Nyocha Ferroxyl

Nrụpụta (oke na nkeji nke ịtụ):Enweghị oke, dịka iwu siri dị.

Etiti oge:Oge ọgwụgwọ n'ozuzu bụ ụbọchị 30. Agbanyeghị, ọ dabere na ọnụọgụ nke usoro ahụ nke ọma.

Ụgbọ njem:Ụzọ njem n'ozuzu bụ site n'oké osimiri, site na Air, site Express, site na ụgbọ oloko, nke ndị ahịa ga-ahọrọ.

Nkwakọ ngwaahịa:

- A ga-eji okpu plastik ma ọ bụ kaadiboodu chebe nsọtụ ọkpọkọ.

- Ngwa niile a ga-akwakọba iji chebe nsọtụ na ihu.

- A ga-akwakọba ngwongwo ndị ọzọ niile site na paịlị ụfụfụ yana nkwakọ ngwaahịa plastik metụtara na ihe plywood.

- Osisi ọ bụla a na-eji kwakọba ga-adị mma iji gbochie mmetọ site na kọntaktị na akụrụngwa eji eme ihe.