Ọkụ na tubes na-enweghị nkebi Titanium

Gr1, Gr 2, Gr 3 niile bụ ụlọ ọrụ mmepụta ihe dị ọcha. Ha nwere ihe eji arụ ọrụ dị elu, arụmọrụ stamping dị mma, enwere ike ịgbanye ya n'ụdị dị iche iche. Ike nke nkwonkwo welded nwere ike iru 90% nke ike nke isi metal, na ịrụ ọrụ ịkpụ dị mma. Titanium tube nwere nnukwu nguzogide corrosion na chloride, sulfide na amonia. Nguzogide corrosion nke titanium n'ime mmiri mmiri dị elu karịa nke aluminom alloys, igwe anaghị agba nchara, na alloys dabeere na nickel. Titanium na-eguzogidekwa mmetụta mmiri.

Titanium alloy bụ tumadi eji maka mmepụta nke ụgbọ elu engine compressor components, sochiri structral akụkụ nke rọketi, akụ ụta na elu-ọsọ ụgbọ elu. N'etiti 1960s, titanium na alloys ya ejiriwo n'ozuzu ụlọ ọrụ na-emepụta electrodes na electrolysis ụlọ ọrụ, condensers na ike ọdụ ụgbọ mmiri, heaters maka mmanụ ụgbọala refining na oké osimiri desalination, na gburugburu ebe obibi na-achịkwa mmetọ ngwaọrụ. Titanium na alloys ya aghọwo ụdị ihe arụrụ arụ na-eguzogide corrosion. Tụkwasị na nke ahụ, a na-ejikwa ya na-emepụta ihe nchekwa hydrogen na ihe nchekwa ihe ncheta.

E jiri ya tụnyere ihe ọla ndị ọzọ, titanium alloy nwere uru ndị a:

- Ike dị elu (ike ike / njupụta), ike nkwụsịtụ nwere ike iru 100 ~ 140kgf / mm2, na njupụta bụ naanị 60% nke ígwè.

- Ọkara okpomọkụ nwere ezi ike, ojiji okpomọkụ dị ọtụtụ narị degrees elu karịa nke aluminum alloy, ọ ka nwere ike ịnọgide na-enwe ike chọrọ na ọkara okpomọkụ, na ike na-arụ ọrụ ruo ogologo oge na okpomọkụ nke 450 ~ 500 ℃.

- Ezigbo nguzogide corrosion. A na-emepụta ihe nkiri edo edo na nnukwu oxide ozugbo n'elu titanium na ikuku, nke nwere ikike iguzogide corrosion site na mgbasa ozi dị iche iche. N'ozuzu, titanium nwere ezigbo nguzogide corrosion na oxidizing na mgbasa ozi na-anọpụ iche, ma nwee nguzogide corrosion ka mma na mmiri mmiri, chlorine mmiri na ngwọta chloride. Mana n'ibelata mgbasa ozi, dị ka hydrochloric acid na ihe ngwọta ndị ọzọ, nguzogide corrosion nke titanium adịghị mma.

- Alloys Titanium nwere arụmọrụ dị ala dị ala yana ihe dị n'etiti etiti dị oke ala, dị ka Gr7, nwere ike idowe ogo plastik na -253 ℃.

- Module nke elasticity dị ala, conductivity thermal dị obere, ọ bụghịkwa ferromagnetic.

BMT bụ ọkachamara n'ịkwapụ ọkpọkọ na tubes titanium na-enweghị nkebi, yana inwe mmepụta kwa afọ nke tọn 5,000. BMT ọkpọkọ na tubes enweghị nkebi na-egosipụta ike dị elu dị elu, nguzogide corrosion, ihe onwunwe cryogenic dị mma, modul elasticity dị ala, conductivity dị ala na enweghị feromagnetism.

BMT nke ọkpọkọ titanium na tube na-enweghị nkebi na-ere nke ọma gburugburu ụwa. A na-eme nleba anya nke ọma n'ihe gbasara ịdịmma, gụnyere nyocha akụrụngwa kemial, nnwale ikuku, nnwale adịghị emebi emebi, nnwale eddy ugbu a na nnwale ultrasonic. Anyị nwekwara n'ibu tesing, ekpuchi tensile ule, flaring ule, flattening ule, ferroxyl ule, RT, X-Ray ule, wdg

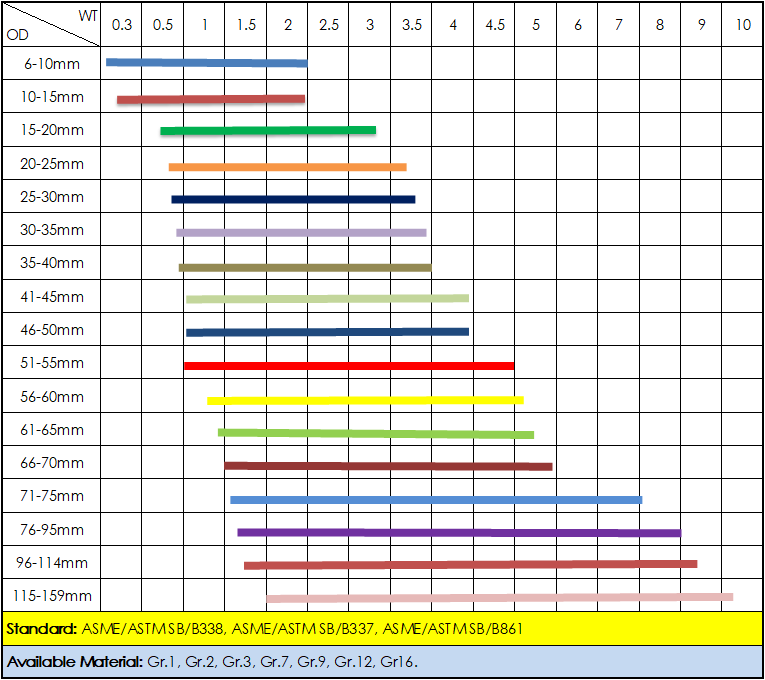

Ọkpọkpọ Titanium enweghị nkebi na Tubes nha nha:

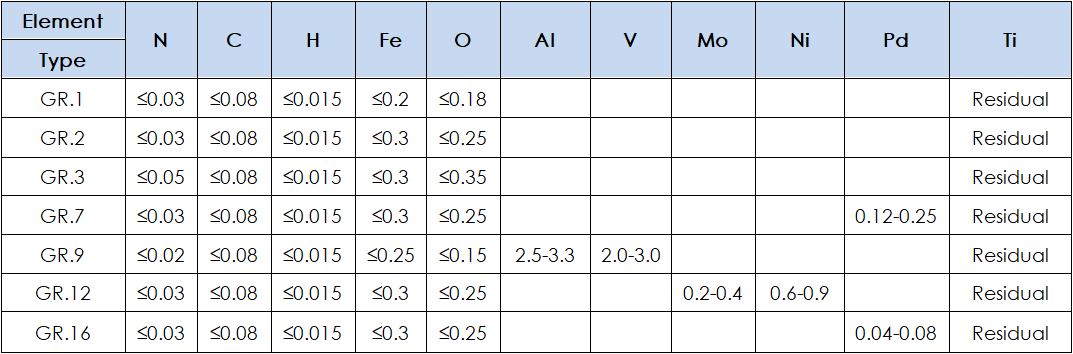

Ngwakọta kemịkalụ ihe dị:

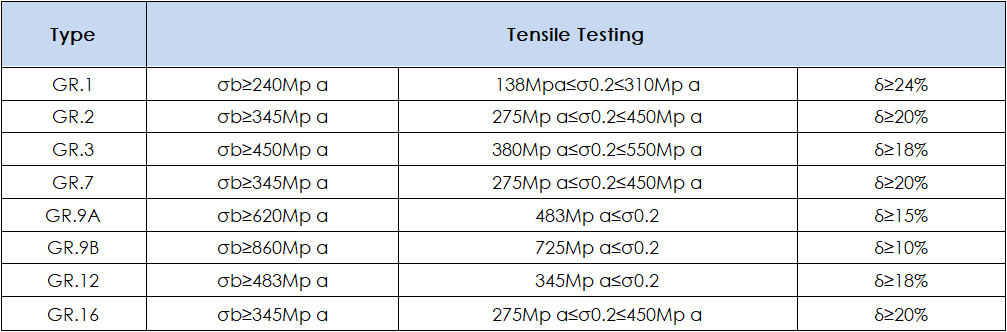

Ihe eji arụ ọrụ dị:

Nyocha nyocha:

- Nyocha ihe mejupụtara kemịkalụ

- Nnwale ihe eji arụ ọrụ

- Nnwale tensile

- Nnwale ọkụ

- Nnwale ire ọkụ

- Nnwale ịgbagọ

- Nnwale Hydro-Static

- Nnwale pneumatic (Nnwale nrụgide ikuku n'okpuru mmiri)

- Nnwale NDT

- Nnwale Eddy-Ugbu a

- Nnwale Ultrasonic

- Nnwale LDP

- Nyocha Ferroxyl

Nrụpụta (oke na nkeji nke ịtụ):Enweghị oke, dịka iwu siri dị.

Etiti oge:Oge ọgwụgwọ n'ozuzu bụ ụbọchị 30. Agbanyeghị, ọ dabere na ọnụọgụ nke usoro ahụ nke ọma.

Ụgbọ njem:Ụzọ njem n'ozuzu bụ site n'oké osimiri, site na Air, site Express, site na ụgbọ oloko, nke ndị ahịa ga-ahọrọ.

Nkwakọ ngwaahịa:

- A ga-eji okpu plastik ma ọ bụ kaadiboodu chebe nsọtụ ọkpọkọ.

- Ngwa niile a ga-akwakọba iji chebe nsọtụ na ihu.

- A ga-akwakọba ngwongwo ndị ọzọ niile site na paịlị ụfụfụ yana nkwakọ ngwaahịa plastik metụtara na ihe plywood.

- Osisi ọ bụla a na-eji kwakọba ga-adị mma iji gbochie mmetọ site na kọntaktị na akụrụngwa eji eme ihe.